Verification by Machine Vision

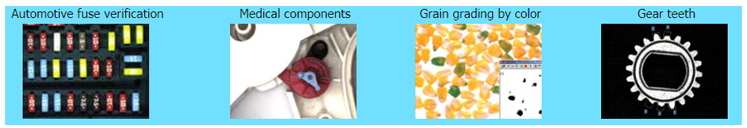

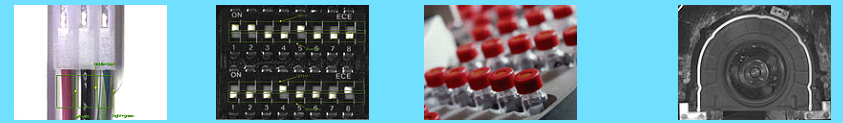

Industrial Machine vision systems are widely used for the verification of parts, assemblies and packaged goods. The range of authentication applications are generally so broad, they utilize the same tools for positioning, measurement, identification and flaw detection. Verification is often combined with other tasks, such as measurement of part dimensions or reading of product barcode, to render 100% product inspection.

Color tools are often used to detect the presence and order of parts on an assembly

Verification Applications

• Vision for Blister pack verification

• Industrial camera for Molded part verification

• Vision inspection for Solder joint verification

• Bottle cap and safety seal verification

• Print verification

• PCB assembly verification

• Cable wiring verification

• Package verification

• Feature (thread, hole, notch) verification

• Machine Vision Capabilities and Tools

• High speed, low light, high resolution image capture

• Search and match tools to find parts and verify assemblies

•Edge, corner, line, circle and line segment detection tools to find part “features”

• Blob analysis tools for counting and dimensioning areas of similar color or contrast on the part

•Counting tools to determine number of parts and indicate missing parts

• Color tools to measure amount and location of colored elements such as automotive fuses, wire, foodstuffs, and pills

• Measuring tools for further qualifying parts and assemblies.