Grups Automation can provision Solution in Foods and beverages application

Flexible Solutions

Vision inspection systems can handle tray and flat packages of any size, and are Programmable to your exact needs.

align="justify"Plastic Film Inspections

Machine Vision inspection Seal and label inspection detects rips and tears in film and labels. Label verification ensures the correct label is present.

Print and Label Quality

Vision inspection system make confident most select label position and readability, and prevent mislabeling errors such as missing or incorrect expiration dates.

Code Reading

Machine Vision Inspection systems validate code/text presence and readability.

Software

Vision inspection system has a quick product changeover interface, wizard-based tool training and statistical reports - and can react to patterned failures.

Vision and ID Solutions for Food and Beverage Applications

M/s Grups Automation delivers product quality, safety, and package integrity

With decades of experience in vision section of food and beverage applications, Sick Vision is exclusively positioned to deliver the highest level of assurance in food and beverage safety, package integrity, and productivity improvements for food and beverage manufacturers, packagers, and the machine builders that serve them.

Whether for food allergen management, assembly verification, quality control, or track and trace, Grups Automation offers the widest product selection for food and beverage industry applications to exactly match the product to the job

Products, combined with powerful vision tools and wide application expertise, enable manufacturing engineers to meet hard packaging, safety, and quality goals

Full Range of Inspection and ID Solutions

Sick Vision System offers the widest range of Vision and ID products available from a single source to provide you with a solution for every application and budget

Sick products help you

• Vision inspection Manage allergens by confirming package/product match, lowering recall risk and reducing problem exposure

• Machine vision inspection system Attain traceability while performing additional product quality checks

• Vision inspection system Reduce scrap by detecting miss labeled products early in the production process

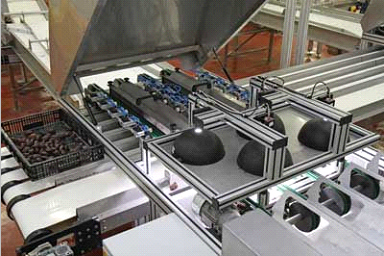

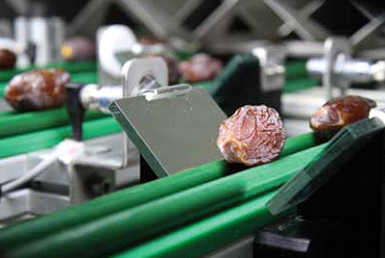

FOOD INSPECTION: Automated system inspects dates at high speed

For Hundreds of years, dates have been a staple of the Middle Eastern diet. One of the most prized varieties—the manufacturing date—is exceptionally large, being roughly 20 mm in diameter and 60 mm in length.

Depending on the picking season, these dates can range in color from yellow to dark brown or crimson. Dates sometimes suffer from "loose skin," a separation of the skin from the soft tissue of the fruit that is usually connected to sugar/moisture levels. Loose skin is an aesthetic defect rather than a taste defect, but it affects the fruit grade and, ultimately, the price.

After harvesting, dates must be inspected for weight, color, and amount of blistering present. In the past, inspection was manual and subject to human error. "Dates are tricky fruits to handle," says Vision expert,