Machine Vision system by Grups Automation

While human inspectors operational on assembly lines visually inspect parts to evaluate the quality of workmanship, machine vision systems use cameras and image processing software to perform parallel inspections. Grups Automation developed Machine Vision inspection plays an significant role in achieving 100% quality control in manufacturing, falling costs and ensuring a high level of customer fulfillment.

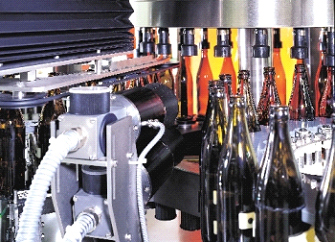

Machine vision system inspection consists of hardly defined tasks such as counting objects on a conveyor, reading serial numbers, and searching for surface defects. Manufacturers often prefer machine vision systems for visual inspections that need high speed, high magnification, around-the-clock operation, and/or repeatability of measurements.

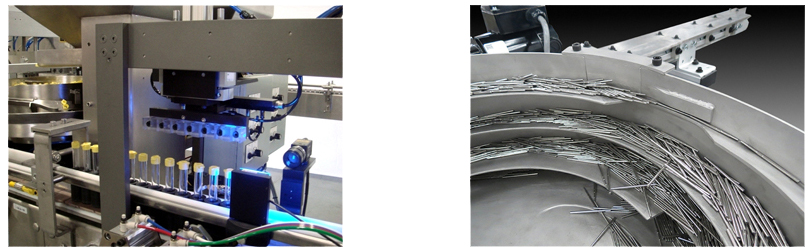

For example, semiconductor fabrication depends greatly on vision inspection technology, without which yields for computer chips would be significantly reduced. Machine vision systems inspect silicon wafers, processor chips, and sub-components such as resistors and capacitors at high speeds with precision and accuracy.

We have developed automatic online inspection system. IN Many cases, it is necessary to conduct visual inspection of any product like Pet, Brush, and Small boxes. Conventional methods of inspection is done by human being . This has its own limitation like Low speed of inspection, Errors, loyalty of manpower. With the help of online inspection methods will solve all above problems

The human eyes are one of the most important organs of the human body and our skills really depend on our capacity to see, recognize and distinguish objects and to estimate distances. Most of the jobs depend on our ability of visual opinion. As amazing as the human sense of vision may be, we must acknowledge that today's production technology more and more often extend well beyond the limits of human visual capacities. This is where

machine vision technology comes in.

What do we actually mean when we talk about machine vision or vision technology? It does not mean graphics or design: instead, it concerns the technology of artificial vision. Cameras and computers give machines or devices the ability to actually "see", to

Identify objects or situations and to make the right decisions accordingly

Machine vision refers to the industrial application of vision technology. It shows the

Understanding and interpretation of technically obtained images for controlling production

Processes. It has evolved into one of the key technologies in industrial automation, which is used in virtually all manufacturing industries

| Following are different application of Vision system . • Online vision inspection of dimension of Product • Online vision inspection of fault in Product • Online vision inspection amount of material filled in Product ( Transparent ) • Online vision inspection of Label Printing on the box • Online vision inspection of position of the product like orientation in degree. • Inspecting of the surfaces of bathtubs for scratch. • Checking whether airbags have been properly installed into cars. • Applying adhesives evenly and correctly. • Verify that welds are strong enough. • Checking paper in the production process for flaws. • Making sure that syringe are manufactured properly. • Finding irregularity on flat glass. • Guiding robots so that they can adapt to changes in their environment. • Reading license plates of cars. • Recognizing and identifying persons. • Reading addresses on parcels and checking their dimensions. |

From a vision inspection system for checking out of tolerance components, counting systems for bagging machines, utilizing the latest pneumatic and electric linear slide systems Grups Automation can supply a system to move control and handle your components.

What are the reward of using machine vision systems? First and foremost, the quality of the

|

QUALITY INSPECTION

Grups Automation Provides machine vision for quality inspection within our systems can fall into three categories:

• Defect Detection

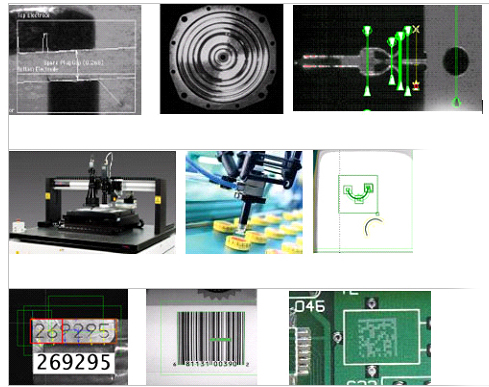

• Tolerance Monitoring with Dimensions measurement

• Component Measurement

DEFECT DETECTION

Defect detection refers to the automatic inspection of customer parts looking for potential defects. Defects can be Minor or affect product Operation. Some defect detection examples include:

• Suture edge sharpness and cut angle

• Glass vial cracks

• Particulate matter

TOLERANCE INSPECTION

A good quality system uses as much response as it can to keep the process in control. Machine vision inspection systems can be difficult in monitoring process related tolerances and allowing the associated control systems to adjust for those trending towards boundary conditions. Typical vision tolerance monitoring systems Grups Automation have implemented include:

• Temperature monitoring by way of IR heat signatures

• Final part positioning

• Punch wear cycles based on cut edge quality and shape

COMPONENT MEASUREMENT

Many products produced by Grups automation have stringent specifications on the dimensions and shape of their essential components. Grups Automation vision systems are widely used to make sure that the components our automation is assembling are up to standard, or else they are rejected before even entering the process. Some typical measurements might be:

• Plastic molded short shot detection

• Component color check

• Tube fill levels

PROCESS AUTOMATION

While some inspection vision systems provide feedback data to the customer about their product quality and process capability, other vision systems are regularly implemented to assist the automation equipment itself to perform the duties it was designed to undertake. These systems can be expanded into these three areas:

• Alignment Feedback and Robot Guidance

• Part Presence and Orientation

• Barcode Traceability and Print Verification

Get the price immediately (currently in stock) click Here....